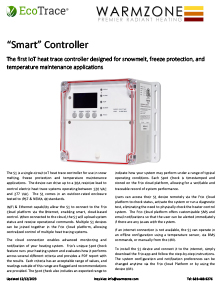

Retrofit Your Interior Floor With Radiant Heat

Warmzone’s RetroHeat electric radiant floor heating makes any room cozy and energy-efficient. Easy to install under tile, hardwood, or carpet, it provides cost-effective underfloor heating without HVAC upgrades. Enjoy precise control, lower energy costs, and luxurious warmth this winter. Call…

Read post